Wooden modular houses – history and how time and technologies made it popular again

5 reasons to choose prefabricated modular house

2018-12-18

One guy experience living in prefabricated wooden modular house

2019-01-07As for wooden modular houses precut and fitted lumber was first offered by Sears in 1916. Prior to 1916, the prospective home builder had to cut their Sears-supplied lumber to appropriate lengths. Construction of a house with pre-cut lumber reduced construction time by up to 40% according to Sears. Sears’s use of “balloon style” framing systems did not require a team of skilled carpenters, as did previous methods. Balloon frames were built faster and generally only required one carpenter. This system used precut timber of mostly standard sizes.

Shipped by railroad boxcar, and then usually trucked to a home site, the average Sears Modern Home kit had approximately 25 tons of materials, with over 30,000 parts.[4] Plumbing, electrical fixtures and heating systems were not included in the base price of the house but could be included, at an additional cost, with the house order. The Modern Homes features of central heating, indoor plumbing, and electrical wiring were the first steps for many families to modern HVAC systems, kitchens, and bathrooms. During the Modern Homes program, large quantities of asphalt shingles became available. Asphalt shingles were cheap to manufacture and ship, and easy and inexpensive to install. A later feature was the use of drywall instead of the plaster and lath wall-building techniques which required skilled carpenters and plasterers. Drywall offered the advantages of low price, ease of installation, and added fire protection. Local building requirements sometimes dictated that certain elements of the house construction be done professionally and varied to meet requirements of each area of the country. For example, requirements for the depth of the foundation varied by climate and terrain and whether the house was being financed by Sears.

Once delivered, many of these houses were assembled by the new homeowner, relatives, friends and neighbors, in a fashion similar to the traditional barn-raisings of farming families. Other homeowners relied on local carpenters or contractors to assemble the houses. In some cases, Sears provided construction services to assemble the homes. Some builders and companies purchased homes directly from Sears to build as model homes, speculative homes or homes for customers or employees.

First manufacturer – Sears Roebuck Co.

Modular buildings are essentially prefabricated buildings taken to a new and larger scale. The use of prefabrication goes back over a hundred years. It started gaining popularity very early in the 20th century. Sears Roebuck Co. sold over 500,000 prefabricated homes between 1910 and the 1940.

Prefabricated modular houses market boom

The end of World War II caused the prefabricated wooden modular houses market to truly explode and greatly evolve. All of the returning soldiers came back to America looking to buy a home and start a family. This demand for homes was greater than the marketplace could handle with the traditional building process. This led people to look for solutions to increase efficiency and lower the cost of new home construction. The prefabricated modular house building process answered both of these needs. There are still prefabricated modular homes being used that were built in the 1950s. These early prefabricated modular homes were much simpler than today’s modular buildings.

In the last twenty years the sophistication has greatly increased with the pioneering work of assembling homes with overhead cranes that have capacity to lift 100 tons. This allowed for larger modules to be constructed and shipped cross-country. The only limitation is the size of each individual module due to the width of the road from the factory to the building site. Today’s prefabricated modular buildings normally consist of 3-6 different modules.

Expanding in real estate market

As the size of prefabricated wooden modular homes has greatly increased since the 1980s so has the customisation options. You can now order a custom designed building that is created by an architect solely for you. The architects plans are then built with modular techniques and the final building is assembled to be as tall and as wide as you wish.

A few current examples of just how well accepted modular units have become, is that they were used in the construction of the new cruise liner Queen Mary 2. The Queen Mary 2 is the largest and most expensive cruise liner. The ship owners choose to use modular passenger cabins to ensure all cabins were built to the higher standards that are available in a factory environment, even their VIP suites utilised the modular building process. Prefabricated modular buildings have also been used to construct McDonalds fast-food restaurants. It is estimated that almost all Americans have been in a modular structure. Since finished modular buildings look the same as traditionally constructed buildings, no one realizes they are in a modular building.

Modular skyscraper

61 Dean Street, Brooklyn’s new modular skyscraper, has been making headlines, both for being the world’s tallest prefabricated modular building and for being overdue and over budget. What’s notable about 461 Dean, is that it approached modular housing from a luxury angle, rather than the usual sci-fi solution to overcrowding and other social crises.

Still, this skyscraper failed to realize the goals of modular design: simplicity, economy, swiftness of construction, repeatability, and flexibility. Moreover, 461 Dean is not alone. In fact, it is merely the latest in a long, vibrant history of mass-modular housing pitfalls.

Modular vs. Prefab

Modular construction and prefabricated construction are different but often overlap — there are usually prefabricated parts of the modular scheme, for instance.

Prefabricated construction consists of any structure designed and produced in a factory prior to building. Prefabricated modular house construction consists of some sort of frame or structure in which smaller units (called modules, which are often fabricated off-site) are assembled onto the frame on-site. Modules range in size and complexity from entire apartments (e.g. 461 Dean Street) to individual rooms. The term module in this context does not refer to individual elements such as single walls, doors or windows, but rather self-enclosed dwelling spaces.

While prefabricated housing has had a long and prosperous history, modular architecture is a much more recent phenomenon. By the time modular construction and planning began, prefabrication had already been around for centuries.

Origins of Modularity

The first prefabricated modular housing schemes can be traced back to Buckminster Fuller, whose flexible housing experiment of the 1920s and 30s, the Dymaxion House, came with things like notably advanced prefabricated bathroom modules.

These modules were shipped to the US military for use during World War II. However, the full extent of Fuller’s modular ideas was never completely realized due to a lack of funding in his Dymaxion company, and the engineer-architect soon moved on to other projects.

The first innovative house

The first successful construction of a fully prefabricated modular home system did not materialize until 1933, with the Winslow Ames House by Robert W. McLaughlin and his company, American House, Inc.

This innovative house was built with the help of a new exterior finishing material called Cemesto, a panel board made partly of sugarcane, patented by the John B. Pierce Foundation. The Winslow Ames House consisted of several room modules serviced by a ‘service core’ to which all bathroom, kitchen, plumbing, and heating systems were attached.

In 1942, the US Government used a similar Cemesto prefabrication system to build the top secret town of Oak Ridge, Tennessee, home of the Manhattan Project, virtually overnight.

They hired the firm Skidmore, Owings, & Merrill, to come up with a scheme called “Flexible Space” – fully prefabricated modular homes flexible enough for the variety of families soon to inhabit this clandestine new place. The houses came in discrete sections, cast in cemento, and assembled on site in slightly varying configurations.

Modularity for the Masses

After the war, the concept of modularity spread to the burgeoning suburbia, albeit in a mellowed-out way, in the form of plug-and-play panel systems of the 1940s and 50s Lustron and Gunnison prefabricated houses.

These popular houses consisted of steel frames with customizable features like a varying selection of kitchen and bath systems, windows and doors, and add-ons like porches, porticos, and garages. While only somewhat modular in design, the houses helped introduce the concepts of modularity to the general public.

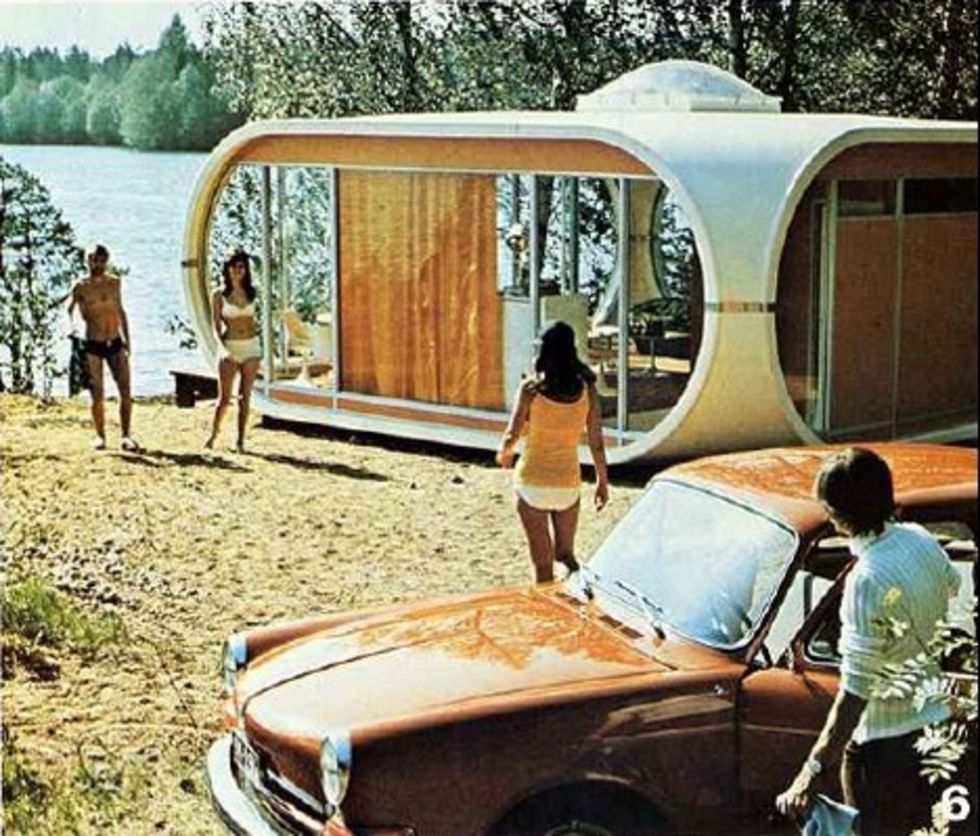

The modular idea captivated many throughout the 1950s, notably the architect and designer George Nelson, most famous for his mid-century modern furniture. Nelson led the transition to new emerging concepts of modularity, expressing modular construction on the exterior (unlike his predecessors, who sought to obscure the modular nature of their designs). His ongoing Experimental House concept combined new materials such as affordable plastics, with the space-age futurism Nelson was most famous for.

In the 1960s, the futuristic aesthetic language pioneered by Nelson and the Eameses and popularized by television programs like Star Trek and current events, including the Space Race and the Atomic Age, became infused in the prefabricated modular housing schemes of the 1960s. These schemes, which focused on installing individual housing units on a mass structural frame, were forward-thinking solutions to the proposed upcoming overpopulation crisis.

Leisure housing

The prefabricated modular home era of the early 60s opened with fanciful leisure housing by the French architect Guy Dessauges, whose elegant capsule houses on pylons offered panoramic views of their scenic locations.

The concept of modularity reached an unattainable level of complexity in the 1964 with Plug In City, a mega-scale modular concept by the British experimental architecture collective Archigram. Though it was never built, Plug-In-City set the stage for the idea of the interchangeable city for the somewhat-dystopian future predicted in the Cold War atmosphere of the 1960s.

Prefabricated modular megastructure

Perhaps the biggest accomplishment of this heydey of modular experimentation was the prefabricated modular megastructure by Moshe Safdie, Habitat 67, built for the 1967 Expo in Montreal.

Habitat 67, a graduate project by Moshe Safdie, who studied at McGill University, consists of up to 12 stories comprised of 354 identical prefab concrete apartments arranged in a variety of combinations. The project focused on the integration of light, fresh air, and open space, in the context of a dense, urban community prototype. The apartments still stand, and still sell for upwards of hundreds of thousands of dollars (a rarity for experimental housing schemes).

On the other side of the world, Japan, confronted by a post-war population and manufacturing boom, developed the architectural style of Metabolism, which focused on flexibility, modularity, and the Archigram-like concept of interchangeable units.

Though the Metabolist group was only active until the 1973 Energy Crisis, they had a large effect on American architects and thinkers, who visited for the 1970 Expo.

Like Archigram, the Metabolists concepts were mostly hypothetical, never reaching past the model stage. However, they did manage to have a few buildings built. The most notorious and interesting of these structures was the 1972 Nagakin Capsule Tower, by Kisha Kurokawa.

The Nagakin Capsule tower consists of 140 self-contained prefabricated capsules, complete with bathrooms, cabinetry, and a built-in HiFi set. The tiny capsules, designed to be removable and replaceable, only measure 7.5 x 6.9 x 12 feet — a predecessor to today’s increasingly popular micro-apartments.

Despite its striking appearance, the tower has been in danger of demolition for over 10 years; for now, preservation efforts have forestalled the potential loss of such an important building.

New era

Unsuccessful developments such as Rudolph’s pushed public taste away from the mass modular concept as the 70s came to a close. The resolution of the 1970s energy crises combined with the new era of Neoliberal economic theory and prosperity created by the technological advantages of the Green Revolution, created a boom in consumerism manifested as house-building during the Reagan era. Americans were all too happy to put the grim weight of social programs and societal turmoil (including failed social housing) of the past two decades behind them and usher in a period of increased private spending and private ownership.

While prefabricated modular apartment concepts retained favorability in the densely populated cities of Europe during this period, the modular housing concepts of the 1980s in America returned to the thinking of the 1940s and 50s, focusing on the individual home rather than the collective housing prototype. The 1980s saw prefabricated modular housing technology applied to the construction of suburban homes, with companies such as Unity Homes devised modular methods of building as an alternative to the often-stigmatized manufactured homes of the time.

These new prefabricated modular houses were constructed from parts in a factory, where a steel frame was used as the chassis on which the house was transported to the construction site. Here, the home was picked up with a crane and assembled on a prepared foundation. The frame then went back to the factory for construction of the next “off frame” modular. These modular methods, whose origins are directly linked to the early cemento houses of Oak Ridge, Tennessee, remain popular in home construction today.

Contemporary Modularity

The great advances in technology during the 1990s and 2000s inspired a new generation of architects to return to the concept of experimental modular housing. Improvements in computer rendering led to innovative manufacturing concepts like the Klip House, whose computer-designed parts could be snapped together like LEGOs.

The flexible nature of Klip House aimed to appeal to those seeking a single family detached home that could adapt to their changing needs. With this system, the need for more space could be solved by simply clipping in another module rather than moving out or building an entirely new home (therefore mitigating the relentless urban sprawl of the last four decades).

The most recent developments in prefabricated modular housing have sought to solve an entirely new problem: urban housing affordability. As more and more wealth moves into cities, and speculation on urban property rises, displacement and gentrification have created an urban housing affordability crisis spanning cities from coast to coast.

An unexpected side effect of this problem is the displacement of young people and creative-types, who have become a new sect of marginalized home-buyers, priced out of the places where their careers can thrive. New types of housing have arisen for those desperately looking for low rents: container houses and modular micro-apartments.

Container housing, a creative reuse approach in which excess or discarded shipping containers are transformed into small homes, hit the mainstream consciousness in 2000, when the firm Urban Space Management completed the Container City I project in the Trinity Buoy Wharf area of London. The project bears many similarities to Rudolph’s Oriental Masonic Gardens, in that several discrete units are assembled into a complex of private homes. The firm has gone on to complete 16 additional projects.

Though popular in Europe, complicated zoning laws in the US have prevented the proliferation of shipping container developments, despite claims that they could be an effective affordable housing solution.

1970’s

The popularity of prefabricated modular homes continued to grow in the 1970s. This led the federal government to enact some changes and regulate the way that these homes were built for safety purposes. It was in 1976 when the U.S. Department of Housing and Urban Development building code was created. It is also known as the HUD code and it sets certain standards for modular and traditional homes.

The way that prefabricated modular homes were built had to be changed to meet the heating codes, plumbing codes, and the electrical systems. The structural designs, the construction, the fire safety and the energy efficiency codes also had to be met. While this changed the way that modular homes had to be built, it didn’t affect its popularity.

People were still buying these homes because it was the best way for struggling families to have their own homes. In 1994, the HUD codes were updated to make the standards even higher for prefabricated modular homes.

Thank you for reading!